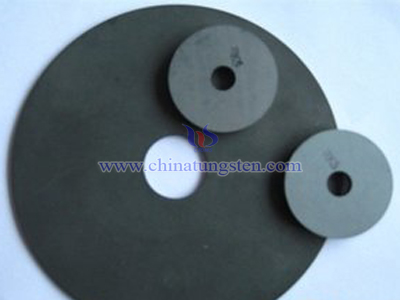

Grade for Making Tungsten Carbide Disc Cutter

Grade |

Equivalent to ISO | Density (g/cm3) | HRA | T.R.S (Mpa) | Applications |

| YC6A> | K10 | 14.9 | ≥92.0 | ≥1860 | Fine grain alloy, good wear resistance This type of tungsten carbide disc cutter is suitable for semi-finishing of chilled cast iron, non-ferrous metal alloy, semi-finishing and finishing of chilled hardened steel and alloy steel. |

| YC8 | K20 | 14.8 | ≥89.5 | ≥2320 | High strength, impact and shock resistance, higher than YC6A, but wear resistance and cutting speed comparatively lower. This type of tungsten carbide disc cutter is suitable for processing of casting iron, non-ferrous metal and alloy as well as non- metallic materials at low cutting speed. |

| YC10X | K40 | 14.8 | ≥91.0 | ≥2150 | Fine grain alloy, good wear resistance. This type of tungsten carbide disc cutter is used for processing hard wood, veneer board, PCB, PVC and alloy. |