Advantages of Tungsten Carbide Disc Cutter

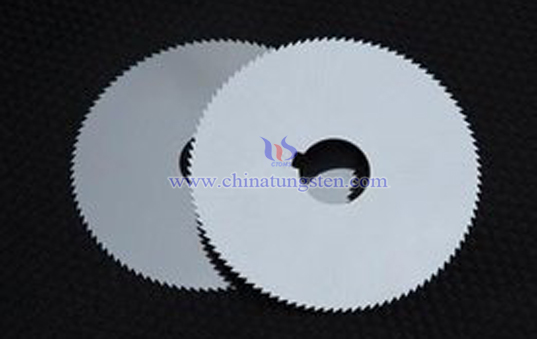

Tungsten carbide is widely used in industry because of its extraordinary properties. Because of its wear resistance and hardness (9.8 Moe's scale), tungsten carbide is ideally suited for wear parts, other machine parts and dies which are subject to severe service conditions, such as high temperatures, corrosion and abrasion.

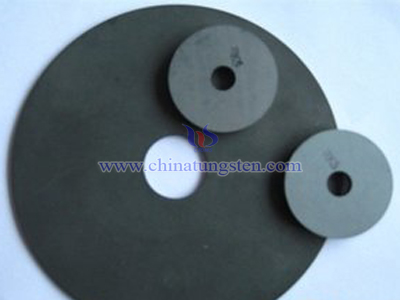

Tungsten carbide disc cutter has the excellent properties of tungsten carbide, which is of high melting point, good hardness, excellent resistance performance on compression, abrasion, corrosion, impact etc.

Due to heavy cutter wear, the costs of replacing and installing new cutters are nearly half of the operating costs in mining operations. Discovery of new disc cutters with significantly improve life are deadly urgent. To develop a new cutter with increased wear resistance, tungsten carbide disc cutter with high superior hardness and hot hardness is selected.